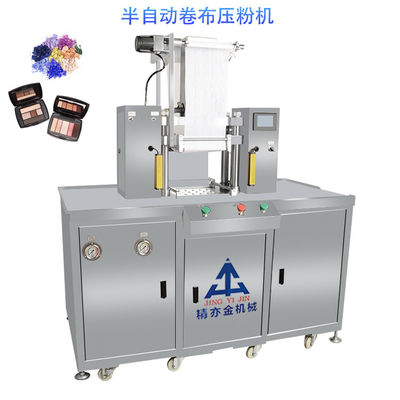

Cosmetic Cream Filling Machine Eight-Color Srew Filling Machine Eyeshadow Concealor Face Color

Description:

This machine is suitable for the filling work of monochrome and multicolor disc lipstick, eye shadow cream, lipstick, semi-dry watercolor, face color and other paste raw materials.

1. The machine adopts piston filling method, and each filling nozzle can set different filling quantification with small quantification error. The nozzle has a return suction device and will not leave the material body.

2. the material body through the place (material nozzle, pump, material cylinder) are equipped with a separate digital display temperature control, suitable for different material body heating temperature adjustment

3. the material bucket is a double layer bucket, the sandwich and thermal oil to heat the material, with the mixing motor, effectively control the mixing speed, make the material 360 degrees heat evenly, effectively control the heating temperature of raw materials. The open and close state of any material barrel can be selected according to the production requirements.

4. with 3000 * 200mm water conveyor belt, set up infrared induction positioning device, high efficiency, manual saving.

5. The size of filling nozzle fixing plate is 200 * 200mm, suitable for different spacing.

Quick Details:

1. Filling Stations: An eight-color filling machine consists of eight individual filling stations, each equipped with a nozzle or valve that dispenses the product into containers. The filling stations are often adjustable to accommodate various container sizes and shapes.

2. Color Management System: The machine incorporates a color management system to ensure accurate color matching and dispensing. This system may include sensors, spectrophotometers, or other color measurement devices to maintain consistent color accuracy throughout the production process.

3. Control Panel: The control panel allows operators to set and adjust various parameters, such as fill volume, fill speed, and color selection. It provides an interface for monitoring and controlling the machine's operation.

4. Conveyor System: A conveyor system is used to transport the containers through the filling stations. It ensures a smooth and continuous flow of containers, optimizing the filling process.

5. Hopper or Reservoirs: The machine typically includes hoppers or reservoirs where the product is stored before being dispensed into the containers. These reservoirs can be equipped with agitators or mixers to maintain the product's consistency and prevent settling.

6. Cleaning and CIP (Clean-in-Place) System: To maintain hygiene and prevent cross-contamination between different colors, an eight-color filling machine may have a cleaning and CIP system. This system allows for thorough cleaning of the filling stations, nozzles, and other components between production runs.

Specification:

| Appearance size: |

1950mm length * 850mm width * 1650mm high |

| weight: |

280 kg |

| Power supply: |

380V50HZ |

| Power: |

16.8KW |

| Maximum withstand pressure: |

8 KG / CM2 |

| Use air pressure: |

3-6 KG / CM2 |

| Maximum temperature resistance: |

150℃ |

| service temperature: |

120℃ |

| Maximum quantification: |

11mL |

| Quantitative accuracy: |

± 0.1 mL |

| Temperature control error: |

± 1℃ |

| material pipe pressure resistance: |

8 KG / CM2 |

| Plate spacing: |

4 mm |

| material barrel stirring speed: |

0~60r / min |

| Capacity: |

up to 1800 mold / hour |

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

- The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

- We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

- The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

- We focus on teamwork and can give full play to everyone's strengths in the team.

- The company has a perfect management system and process to ensure the efficiency and quality of the service.

- We focus on innovation and development, and are able to continuously launch new products and services.

- The company has a good reputation and reputation, and can win the trust and support of customers.

- We focus on customer experience and can provide customers with comfortable and convenient services.

- The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

- We pay attention to the training and development of employees, which can improve their professional quality and ability.

- The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

Detailed drawing:

finished products:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!