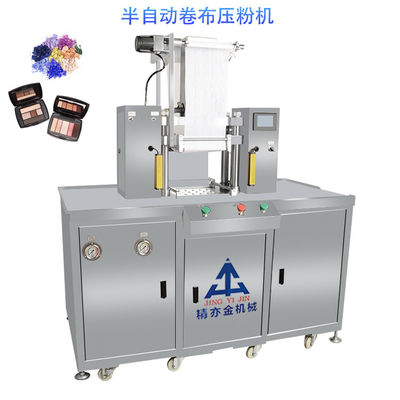

Cosmetic Cream Filling Machine Full-Auto Single-Head Cream Filling Machine

Description:

1. This production line consists of filling and induction belt brake conveyor belt. The production line is applicable to all kinds of paste / liquid products quantitative filling such as: cooling oil, gold oil, foundation cream, wax, pelvic lipstick, lip honey, eye shadow cream and other pelvic wide mouth packaging needs to be heated,

2. With mixing double-layer bucket sandwich heating, can ensure the uniform heating of raw materials. The pump and filling nozzle are independent heating, without heating dead corners. Another foot switch can be selected automatically or manually according to the product.

3. Through the gear type quantitative filling method, the more stable, fast, low noise to make the production environment more comfortable, the filling range of 1 gram without upper limit, to meet the diversification of filling products

4. PLC program is adopted to control, the set parameters (quantitative, time and temperature control setting) are set by PLC interface, and the required capacity can be accurately set, which has great practicability and benefits for multiple types and diversified users.

5. With 3000 * 200mm water conveyor belt, infrared induction positioning device, high efficiency, labor saving.

Quick Details:

1. Container Placement: Empty containers are placed on a conveyor or a platform, ready to be filled.

2. Heating System: The heating system of the machine is activated to warm the liquid or viscous product to a desired temperature. This is particularly useful for products that need to be filled at elevated temperatures to maintain their properties or viscosity.

3. Product Reservoir: The machine has a reservoir or a holding tank where the liquid or viscous product is stored. The reservoir is usually equipped with a heating mechanism to maintain the desired temperature of the product.

4. Gear Pump: The machine utilizes a gear pump, which is a positive displacement pump with two or more interlocking gears. As the gears rotate, they create a vacuum that draws the product from the reservoir and pushes it through the pump.

5. Filling Nozzles: The gear pump is connected to a set of filling nozzles. The number of nozzles can vary depending on the machine's design and the desired filling speed. The nozzles are positioned above the containers.

6. Filling Process: As the gears of the pump rotate, the liquid or viscous product is pushed through the filling nozzles and dispensed into the containers. The filling process is usually controlled by sensors or timers to ensure accurate and consistent fill levels.

7. Container Sealing: After filling, the containers are typically moved to another station for sealing, capping, or labeling, depending on the specific packaging requirements.

Specification:

| power: |

3KW |

source: |

220V/50HZ |

| air supply : |

0.3-0.8Mpa |

Production capacity: |

30-70 pcs/min |

| Bucket volume: |

20L/70L |

Bucket material |

stainless steel SUS304 |

| display screen |

Huichuan |

PLC |

Huichuan |

| Speed adjustment motor |

Jingyan |

Stir the motor |

Dongyang |

| Body size: |

800*820*1600mm / 1000*950*1550mm |

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

- The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

- We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

- The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

- We focus on teamwork and can give full play to everyone's strengths in the team.

- The company has a perfect management system and process to ensure the efficiency and quality of the service.

- We focus on innovation and development, and are able to continuously launch new products and services.

- The company has a good reputation and reputation, and can win the trust and support of customers.

- We focus on customer experience and can provide customers with comfortable and convenient services.

- The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

- We pay attention to the training and development of employees, which can improve their professional quality and ability.

- The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

Detailed Drawing:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!