Cosmetic Cream Filling Machine Quantitative Air Cushion BB Frost Filling Machine Pneumatic

Description:

This machine is ideal for filling semi-liquid raw materials such as air cushion BB cream essence, foundation liquid, body milk isolation cream, and other semi-liquid raw materials.

Quick Details:

1. Container Positioning: The containers to be filled are placed on the filling machine, either manually by an operator or automatically by an automated container handling system. Bottles, jars, tubes, and other suitable vessel types can be used as containers.

2. Product Supply: The product to be filled is kept in a reservoir or supply tank that is linked to the filling machine. The product can be a liquid, gel, cream, or other similar substance that can be filled pneumatically.

3. Filling Nozzle and Control System: The filling machine has a filling nozzle or a filling head that is designed to correctly dispense the product into the containers. A pneumatic control system controls the filling nozzle, which is connected to the product supply system.

4. Pneumatic Control: The filling machine's pneumatic control system regulates the filling operation. It is often made up of pneumatic valves, pressure regulators, and sensors that work together to control product flow and filling volume.

5. Filling Process: The filling process is initiated by the operator or an automated control system. The containers are placed beneath the filling nozzle, and the filling operation is started.

6. When the pneumatic control system opens the valve, the product flows into the container.

7. Volume Measurement: Pneumatic quantitative filling machines use a variety of technologies to correctly estimate the filling volume.

8. Adjustment and Filling Accuracy: Pneumatic quantitative filling machines can be modified to achieve the appropriate filling accuracy. Filling parameters such as filling time and pressure can be adjusted to fit the volume needs of the product being filled.

9. Repeat Filling: Depending on the production requirements, the filling machine can be set to repeat the filling procedure for many containers in continuous or batch mode.

10. Cleanup and Maintenance: After the filling process is over, the filling nozzle or head is frequently built for easy cleaning and maintenance to prevent cross-contamination or product residue buildup.

Specification:

|

Source

|

220V/ 50Hz

|

|

Air supply

|

0.3-0.8Mpa

|

|

Outline dimension(L*W*H)

|

550*430*1500MM

|

|

Pneumatic pressure

|

0-6KG/CM²

|

|

Filling range

|

5-40ML 10-150ML 20-250ML 50-500ML

|

|

Filling accuracy

|

±0.1ML

|

|

Working table height

|

750MM(H)

|

|

Production capacity

|

20-50pcs/min

|

|

Body material

|

stainless steel(SUS304)

|

|

Bucket volume

|

20L

|

|

Machine net amount

|

70KG

|

Uses and function:

1. The nozzle has an absorption device, there is no remaining material, and the proportional valve and pipe are simple to reinstall and clean.

2. Disassembly of the material bucket, big specification items can be dismantled the material bucket directly pumping filling, convenient and rapid.

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

-

The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

-

We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

-

The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

-

We focus on teamwork and can give full play to everyone's strengths in the team.

-

The company has a perfect management system and process to ensure the efficiency and quality of the service.

-

We focus on innovation and development, and are able to continuously launch new products and services.

-

The company has a good reputation and reputation, and can win the trust and support of customers.

-

We focus on customer experience and can provide customers with comfortable and convenient services.

-

The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

-

We pay attention to the training and development of employees, which can improve their professional quality and ability.

-

The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

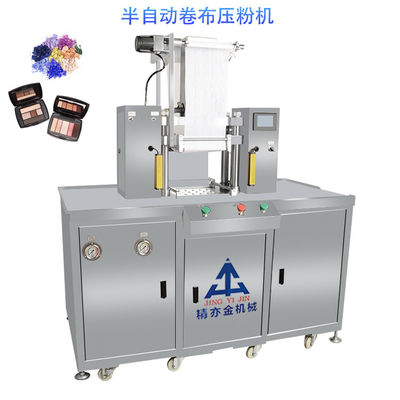

Detailed picture:

Packing:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!