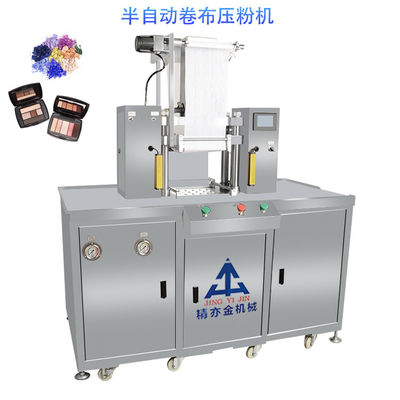

Customized Automatic Production Line Crystal Eye Patch Filling Machine

Description:

1. Purpose: suitable for die-cutting operations.

2. Specifications: suitable for crystal eye mask.

3. Length range: 200~260mm, width range: 150~260mm.

4. Voltage and power: Voltage: 220V; power: 3000W.

5. Responsibility and responsibility: the operator is responsible for the use and daily maintenance.

Quick Details:

1. Filling Stations: The machine consists of one or multiple filling stations, depending on the production requirements. Each filling station is equipped with a nozzle or valve designed to dispense the eye patch formulation into the containers.

2. Container Feeding System: The machine incorporates a system for feeding empty eye patch containers or pouches to the filling stations. This system can use conveyors, magazines, or other mechanisms to ensure a continuous supply of containers for filling.

3. Formulation Delivery System: The eye patch formulation, which can be a gel, cream, or other materials, is stored in a reservoir or tank within the machine. It is then delivered to the filling stations through a piping system or pumps. The delivery system ensures a consistent flow of the formulation to each filling station.

4. Control Panel: The machine features a control panel that allows operators to set and adjust various parameters, such as fill volume, fill speed, and other filling parameters. The control panel also provides an interface for monitoring and controlling the machine's operation.

5. Level Sensors: To ensure accurate and consistent fill levels, the machine may incorporate level sensors that detect the amount of eye patch formulation in each container. These sensors help maintain uniform filling throughout the production process.

6. Sealing Mechanism: After the eye patch containers are filled, the machine may include a sealing mechanism to seal the filled containers. This can involve heat sealing, ultrasonic sealing, or other sealing methods suitable for the packaging materials used for the eye patches.

7. Cleaning and CIP (Clean-in-Place) System: To maintain cleanliness and prevent cross-contamination, an eye patch filling machine may have a cleaning and CIP system. This system enables efficient cleaning of the filling stations, nozzles, and other components between production runs.

Specification:

| Touch screen |

Weinview |

| PLC |

SIEMENS |

| Electric machinery |

Jingyan, Germany |

| Servo motor |

Panasonic |

| Refrigeration compressor |

Taikang, France |

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

- The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

- We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

- The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

- We focus on teamwork and can give full play to everyone's strengths in the team.

- The company has a perfect management system and process to ensure the efficiency and quality of the service.

- We focus on innovation and development, and are able to continuously launch new products and services.

- The company has a good reputation and reputation, and can win the trust and support of customers.

- We focus on customer experience and can provide customers with comfortable and convenient services.

- The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

- We pay attention to the training and development of employees, which can improve their professional quality and ability.

- The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

Detailed drawing:

finished products:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!