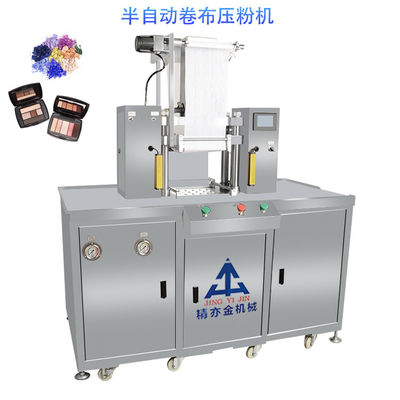

Air Cushion BB Frost Filling Machine Inner Ring Pressing Machine Capping 3-5 Seconds / Box

Description:

Air cushion BB cream vacuum machine is a vacuum way to breathe liquid BB cream into cotton, can effectively improve the speed of production,

Low secondary pollution. The upper and lower molds are fixed on the machine, a style can be produced with only one mold, and it is easy to install the mold.

The action mode can be manual mode or footswitch mode according to the operation situation or the user requirements.

Quick Details:

1. Component Placement: The component onto which the inner ring will be pressed is prepared and positioned on the machine. This component can be a shaft, a raceway, or any other part of the assembly that requires the inner ring.

2. Inner Ring Preparation: The inner ring, which is typically a separate component, is prepared for assembly. This may involve cleaning, lubricating, or aligning the inner ring to ensure proper fit and function.

3. Pressing Mechanism: The inner ring pressing machine is equipped with a pressing mechanism that exerts force or pressure to mount the inner ring onto the component. The specific pressing mechanism can vary depending on the design of the machine, but it often includes hydraulic or pneumatic cylinders, mechanical presses, or specialized tools.

4. Alignment and Positioning: The inner ring and the component are aligned and positioned properly within the pressing machine. This ensures that the inner ring will be mounted accurately and securely onto the component.

5. Pressing Operation: Once the alignment is confirmed, the pressing operation is initiated. The pressing mechanism applies controlled force or pressure to gradually press the inner ring onto the component. The force is exerted in a way that ensures a tight fit, securely locking the inner ring in place.

6. Monitoring and Quality Control: Some inner ring pressing machines may include monitoring and quality control features to ensure the accuracy and integrity of the assembly process. These features can include sensors, load cells, or monitoring systems that measure and verify the applied force, position, or other relevant parameters during the pressing operation.

7. Unloading and Transfer: After the pressing operation is completed, the component with the mounted inner ring is unloaded from the machine. It can then be transferred to the next stage of the manufacturing or assembly process.

Specification:

| Source |

220V/ 50Hz |

| Power |

100W |

| Air supply |

0.3-0.5Mpa |

| Outline dimension(L*W*H) |

600*460*1350MM |

| Pneumatic pressure |

0-6KG/CM² |

| Production capacity |

20-50pcs/min |

| Suction time |

3-5 Seconds / Box |

| Mold size |

Customizable |

| Machine net amount |

About 50 kilograms |

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

- The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

- We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

- The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

- We focus on teamwork and can give full play to everyone's strengths in the team.

- The company has a perfect management system and process to ensure the efficiency and quality of the service.

- We focus on innovation and development, and are able to continuously launch new products and services.

- The company has a good reputation and reputation, and can win the trust and support of customers.

- We focus on customer experience and can provide customers with comfortable and convenient services.

- The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

- We pay attention to the training and development of employees, which can improve their professional quality and ability.

- The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!