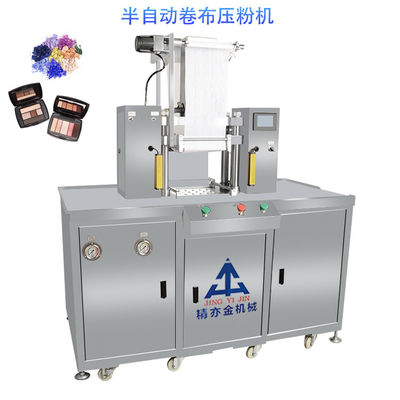

Powder Production Line Screw Powder Filling Machine 750mm (L) * 550mm (W) * 1680mm (H)

Description:

1. Powders and small particles can be filled.

2. Screw filling and PLC control, man-machine interface operation, step motor drive.

3. Material barrel belt stirring, the speed is adjustable.

4. A wide range of application, can be used for different objects filling, accurate filling volume, pedal filling, convenient and simple.

5. Operation, color change, easy maintenance, less fault.

Quick Details:

1. Container Placement: Empty containers, such as bottles, jars, or pouches, are positioned or conveyed to the filling machine. The containers are typically held securely in place to ensure accurate filling.

2. Powder Supply: The machine is equipped with a powder supply system, usually a hopper or reservoir, where the powdered substance is stored. The hopper can be manually loaded or connected to a powder handling system for automated feeding.

3. Filling Mechanism: The key component of a screw powder filling machine is the rotating auger screw. The screw is made up of a helical blade that rotates within a tube or nozzle. The rotation of the screw transports the powdered substance from the hopper to the discharge point.

4. Filling Process: As the auger screw rotates, the powdered substance is drawn into the flights of the screw and conveyed toward the discharge point. The rotation speed of the screw can be adjusted to control the flow rate and achieve the desired filling volume.

5. Discharge and Control: At the discharge point, the powdered substance is dispensed into the containers. The machine typically includes mechanisms to control the flow rate and cut-off the powder flow accurately, ensuring precise filling.

6. Leveling and Settling: Some screw powder filling machines may incorporate leveling or settling mechanisms to ensure uniformity and proper density of the filled product. These mechanisms can help achieve consistent fill levels and minimize air pockets or voids in the powder.

7. Container Closure: Once the powder filling process is complete, the filled containers are typically transferred to the next stage of the packaging line for closure, such as capping, sealing, or labeling.

Specification:

Voltage: 220 V 50 Hz

Dimensions: 750mm (L) * 550mm (W) * 1680mm (H)

Powder bucket capacity: 45L

Product types: eye shadow powder, prickly heat powder, facial mask powder, all kinds of powder

Operator: 1-person person

Maximum filling capacity: 10-120g

Maximum capacity (30g 2000 mesh talc powder meter): 2000-2400 pcs / h

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

- The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

- We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

- The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

- We focus on teamwork and can give full play to everyone's strengths in the team.

- The company has a perfect management system and process to ensure the efficiency and quality of the service.

- We focus on innovation and development, and are able to continuously launch new products and services.

- The company has a good reputation and reputation, and can win the trust and support of customers.

- We focus on customer experience and can provide customers with comfortable and convenient services.

- The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

- We pay attention to the training and development of employees, which can improve their professional quality and ability.

- The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

detailed drawing:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!