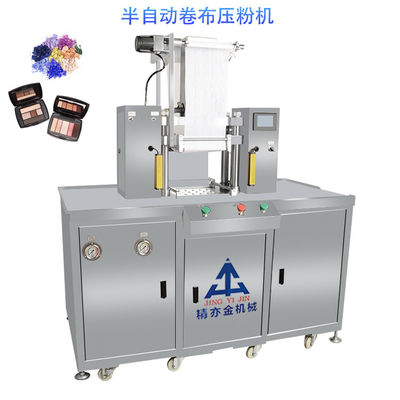

Powder Production Line Semi-auto Powder Pressing Machine 1480 * 680 * 1600MM 2.8KW

Description:

This product is designed for cosmetics powder, suitable for the production of eye shadow, eyebrow powder, powder cake and other powder manufacturing. Double press start design, to ensure the safety of the user, using two stages of pressure, can adapt to the difficult processing of powder raw materials.

1. Powder pressing time, pressing time and powder pressing times can be set on the PLC interface, and the operation is simple.

2. Install the guide device to make the pressure balance. The pressed powder is smoother and cleaner.

3. double switch setting, employees in the process of use, more safe.

4. using PLC and text display control, the operation is more convenient, more stable and reliable performance.

Quick Details:

1. Powder Preparation: The powder formulation is prepared by blending the desired ingredients, which can include active pharmaceutical ingredients (APIs), excipients, binders, lubricants, and other additives. The powder blend is typically uniform and free-flowing.

2. Loading: The powder blend is loaded into a die cavity or a mold cavity within the pressing machine. The die cavity is usually a hollow space of a specific shape and size, designed to create the desired final product. The powder can be manually loaded or fed automatically into the cavity using a hopper or feeding system.

3. Compression: Once the powder is loaded, the pressing machine applies pressure to the powder in the die cavity. The pressure can be applied through various means, such as hydraulic systems, mechanical systems, or pneumatic systems. The applied pressure compacts the powder particles, reducing void spaces and creating a solid and compacted product.

4. Ejection: After the compression process, the compacted powder product is ejected from the die cavity. This can be done manually or using an automated ejection system, depending on the machine's design.

5. Post-Processing: The compacted powder product may undergo additional post-processing steps, depending on the desired final product. This can include surface treatment, polishing, coating, or packaging.

Specification:

| Source |

380(220)V/ 50Hz |

| Aggregate capacity |

2.8KW |

| Outline dimension |

1480x680x1600MM |

| Working table height |

880MM(H) |

| Optimal pressure range |

0-140KG/CM² |

| Production capacity |

35-60pcs/min |

| Machine net amount |

320Kg |

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

- The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

- We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

- The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

- We focus on teamwork and can give full play to everyone's strengths in the team.

- The company has a perfect management system and process to ensure the efficiency and quality of the service.

- We focus on innovation and development, and are able to continuously launch new products and services.

- The company has a good reputation and reputation, and can win the trust and support of customers.

- We focus on customer experience and can provide customers with comfortable and convenient services.

- The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

- We pay attention to the training and development of employees, which can improve their professional quality and ability.

- The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

detailed drawing:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!