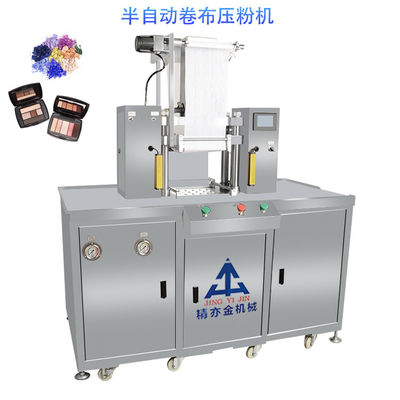

Powder Production Line Laboratory Powder Baking And Pressing Machine 220V / 50Hz

Description:

This machine is cosmetics makeup powder pressing wet powder, baking powder machine, the use of cylinder to control the strength of pressure powder.

Special process powder pressure mold, can discharge the excess raw material water, control the height of powder pressure

The staff operation is simple, convenient and fast. The machine is easy to clean and covers a small area.

Quick Details:

1. Powder Preparation: The raw materials for the powder, such as pigments, binders, fillers, and other additives, are mixed together to create a uniform powder blend. This blend is typically prepared in advance and can be adjusted based on the desired color, texture, and performance of the final product.

2. Baking: The powder blend is placed in trays or molds and transferred to an oven or baking chamber within the machine. The baking process involves subjecting the powder to controlled heat for a specific duration. This helps to evaporate any volatile components, improve the texture, and enhance the adhesion of the powder particles.

3. Cooling: After the baking process, the trays or molds are removed from the oven and allowed to cool down. This step is crucial to ensure that the powder solidifies and retains its shape.

4. Pressing: Once the powder has cooled, the trays or molds are placed into the pressing section of the machine. A pressing mechanism, typically hydraulic or pneumatic, applies pressure to compress the powder particles together, forming a solid and compact cake. The pressure applied can be adjusted based on the desired density and hardness of the final product.

5. Ejection: After the pressing process, the compacted powder cakes are ejected from the trays or molds. The cakes can then be further processed, such as by adding decorative imprints, embossing, or applying a protective layer.

Specification:

| source |

220V 50Hz |

| power |

0.2KW |

| Vacuum pump power |

0.15KW |

| Cylinder model |

125*150 |

| Powder izer size (L * W * H) mm |

550*450*1000 |

| Pressure plate size (L * W) mm |

32*16 |

Advantages:

-

We have a high-quality team that can provide professional services for our customers.

- The company has advanced technology, equipment and facilities, which can meet the various needs of customers.

- We pay attention to the needs of customers, and can provide customized services according to customers' requirements.

- The company has rich experience and professional knowledge, and can provide customers with a full range of solutions.

- We focus on teamwork and can give full play to everyone's strengths in the team.

- The company has a perfect management system and process to ensure the efficiency and quality of the service.

- We focus on innovation and development, and are able to continuously launch new products and services.

- The company has a good reputation and reputation, and can win the trust and support of customers.

- We focus on customer experience and can provide customers with comfortable and convenient services.

- The company has a wide range of partners and resources that can provide customers with more choices and opportunities.

- We pay attention to the training and development of employees, which can improve their professional quality and ability.

- The company has a perfect after-sales service system, which can timely solve customer problems and difficulties.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!